Sand: One of the World’s Most Used Resources

Besides water, sand is the most used natural resource in the world. With the advancement of civilization, the demand for sand has only increased. With desert sand being virtually useless, the world turns to high quality, round to sub-round silica sand for all of its production means.

History of Using Sand

Sand has been used for centuries, dating back to 6000 BC. For example, sand has been noted to have been used for the production of tools within ancient civilizations and melting sand to create glass beads in Ancient Egypt.

Even in the Middle East in around 1300 BC, early builders were known to coat their clay buildings with thin limestone layers that reacted chemically and created a stronger substance that held up well in the elements- one of the first uses of sand/sand like substances that led to the creation of concrete!

In the United States, glass was made in Jamestown, Virginia as early as 1601. Sand has always played an important part of the production of many things and now we rely on it for even the production of turf fields for sports and recreation.

Centuries later and we’re still relying heavily on sand and ever finding new ways to use it. In fact, the demand for frac sand is relatively recent in comparison. When the oil and gas companies made hydraulic fracturing its main method of production in 2010, frac sand’s demand skyrocketed.

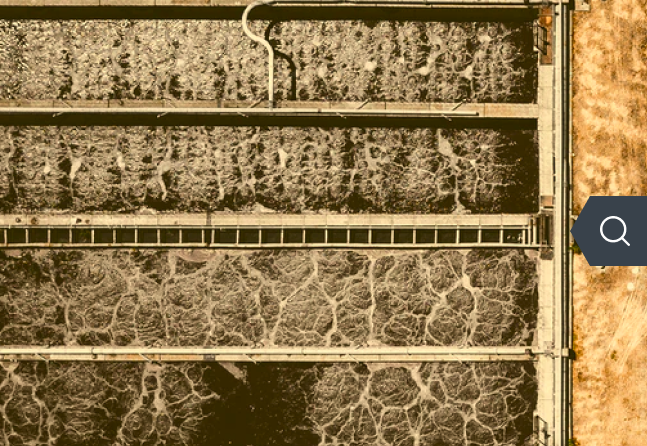

These days, among many uses of sand, we rely on it for water filtration in small and large scales. In fact, most communities do use sand filtration as their main filtration system, being the most widely used means of filtration.

But did you know that even the Ancient Egyptians used an early way of water filtration using clay pots to filter their water? Even then, we still relied on sand for our everyday needs, and the need grows stronger by the day.

Types of Sand Used

It’s only natural that sand has become an integral part of our modern society and even has its place in the creation of technology and advancements in technology and science. But what kind of sand is used for these various means of production? The answer is pretty simple- for our modern usages of sand, the world relies heavily on silica sand.

Desert sand is far too eroded by wind to be used for any sort of production means, so that role falls on the shoulders of silica sand. High quality silica sand is used for so many things, like foundry and casting, water filtration and frac sand as well.

Our high-quality, round to sub-round silica sand can be used in many ways, including:

Turf Infill: silica sand used for turf infill creates a more natural feel for synthetic grass because it is less abrasive. It provides a more solid impact absorption and provides good drainage.

Brick Sand: simply, it is sand used for making bricks. At PFS Aggregates, the sand we use for bricks is a high-quality fine sand that is excellent for the brick making process and end product.

Roofing Sand: Roofing sand refers to the way that our sand can be used. It’s round shape makes it a great option for many projects as silica sand is ideal for ceramic tiles and specialty composite shingles that may be used in roofing materials. .

Water Filtration: high grade, round sand that is highly compaction resistant are just a few reasons why out silica sand is great for water well filtration and for a multitude of other applications.

Glass sand: The majority of most glass production uses up to 90% silica sand as the main component, glass sand is a major factor in the production of industrial glass.

Our high quality silica sand at PFS Aggregates is composed of 99% silica quartz, meaning our sand has less contaminants than other sands and allows for the best combination of hardness, heat resistance and coloration when producing glass

Frac Sand: uniform, round and crush resistant grains are critical characteristics required in the petroleum and hydrocarbon industry. At PFS Aggregates, our sand achieves all this and more- unlike other sand varieties that do not have the grit to stand up to intense pressure during the hydraulic fracturing process.

The roundness of the grains is probably the most important aspect of any frac sand, so you will want to make sure any sand you use for a fracking application is round and will withstand pressure.

Building Sand: The ideal sand for building/construction sand is a round to sub-round shapes grain because this creates a resistance to compaction, making it great for a filler or sublayer to support any heavy construction. Many of our modern day industrial applications call for massive quantities of sand from the structures, to glass, to supporting layers and walls.

Foundry/ Casting Sand: Foundry sand is known as casting sand because it’s uniformly sized round grains are bonded to form molds for metal casting. These castings are the backbone for so many engineering and manufacturing industries and their projects

Concrete Sand: premium concrete sand contains larger grains than building or brick sand, and is washed and screened to ensure there are no pebbles and rocks. Concrete sand is in extreme demand ascivilization advances.

How is Sand Used?

So many things around us rely on or are made of sand- so many that we probably don’t even think about it. But sand is ingrained into the structure of modern society and without it, many things would be less efficient or cease to exist in general.

From bricks to water filtration, glass to construction, roofing tiles to artificial sports surfaces sand is used for so many things that space on this website doesn’t allow listing them all.

With filtration, it is used for small-scale filters for mass production, salt and chlorine pool filters, and cooling and heating system filters as well as large industrial complexes that filter water and chemicals.

Sand is a key player in the aerospace, automotive and mining industry as well. Without sand and the advancements over time in how we have learned to use sand, we would not be where we are today in our modern society.

At PFS Aggregates, we’re proud to be a part of the above mentioned industries and proud to provide the best quality of round to sub-round silica sand to our clients consistently. With 80 years of combined sand production and processing experience, our modern and efficient facility is capable of producing mass qualities of sand that is available to all of our clients at a fair cost.

Give us a call today at 325-425-0866 and speak to one of our experts about our high quality silica sand to get you started today!